R622

*Use appropriately sized wire.

All circuits shall be wired with appropriately sized insulated copper wire

(

Table 8‑4 Breaker and wire sizing

|

Application |

Minimum Wire Size |

|

31 – 40A breaker protected circuit |

12 AWG (13 SWG or 4 mm2) |

|

21 – 30A breaker protected circuit |

14 AWG (16 SWG or 2.5 mm2) |

|

6 – 20A breaker protected circuit |

18 AWG (19 SWG or 1 mm2) |

|

11-20A fuse protected circuit |

|

|

Between the |

|

|

Compressor outputs from the

|

|

|

Between the |

|

|

Between the |

22 AWG (22 SWG or 0.5 mm2) |

|

Between the |

|

|

Kraken x60 Powerpole Adapter protected circuit |

|

|

≤5A breaker protected circuit |

|

|

≤10A fuse protected circuit |

|

|

≤2A fuse protected circuit VH-109 Passthrough per R626 |

24 AWG (24 SWG or .25 mm2) Cat5e/6/7/8 cable, 2 pairs |

|

roboRIO PWM port outputs ≤1A fuse protected circuit |

26 AWG (27 SWG or 0.14 mm2) Cat5e/6/7/8 cable, single pair |

|

|

28 AWG (29 SWG or .08 mm2) |

Wires that are recommended by the device manufacturer or originally attached to legal devices are considered part of the device and by default legal. Such wires are exempt from this rule, provided they are powered by the smallest value fuse or breaker which permits proper device operation.

In order to show compliance with these rules, teams should use wire with clearly labeled sizes if possible. If unlabeled wiring is used, teams should be prepared to demonstrate that the wire used meets the requirements of this rule (e.g. wire samples and evidence that they are the required size).

R626 *VH-109 PoE passthrough. The VH-109 PoE output may be used only under the following conditions:

A.

The device being powered is a

B. The connection is made using standard Cat5e/6/7/8 cable.

C. The VH-109 is powered using the 12V input terminals with 18AWG wire or larger (it may additionally be powered using the PoE input if desired).

R623

*Use only appropriate connectors.

Branch circuits may include intermediate elements such as

Slip rings containing mercury are prohibited per R203.

R616 *Power radio as specified – Part 1. The wireless bridge (radio) power must be supplied by either:

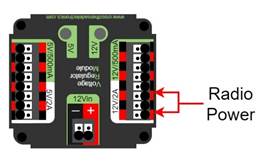

A.

the 12V 2A output of a CTR Electronics Voltage Regulator

Module (

Figure 8‑12

Radio power source from a

B.

using an Ethernet cable between a REV Radio Power Module

(

C.

directly from the

Note that this prohibits using any other active PoE

injector device to power the radio but does not prohibit using any PASSIVE

CONDUCTORS to inject the

The use of a

R601

*Battery limit – everyone has the

same power. The only legal source of electrical energy for the

A. Nominal voltage: 12V

B. Nominal capacity at 20-hour discharge rate: minimum 17Ah, maximum 18.2Ah

C. Shape: Rectangular

D. Nominal Dimensions: 7.1 in. x 3 in. x 6.6 in., +/- .1 in. for each dimension (~ 180 mm x 76mm x 168 mm, +/- 2.5 mm for each dimension)

E. Nominal weight: 11lbs. to 14.5 lbs. (~5 kg. to 6.5 kg.)

F. Terminals: Nut and bolt style

"Nut and bolt style" refers to any style battery terminal where the connector is secured to the battery using a threaded fastener.

Examples of batteries which meet these criteria include:

A. Enersys (P/N NP18-12, NP18-12B, NP18-12BFR),

B. MK Battery (P/N ES17-12),

C. Battery Mart (P/N SLA-12V18),

D. Sigma (P/N SP12-18),

E. Universal Battery (P/N UB12180),

F. Power Patrol (P/N SLA1116),

G. Werker Battery (P/N WKA12-18NB),

H. Power Sonic (P/N PS-12180NB),

I. Yuasa (P/N NP18-12B),

J. Panasonic (P/N LC-RD-1217),

K. Interstate Batteries (P/N BSL1116), and

L. Duracell Ultra Battery (P/N DURA12-18NB).

Teams should be aware that they may be asked to provide documentation of the specifications of any battery not listed above.

Batteries should be charged in accordance with manufacturer’s specification. (Please see the FIRST Safety Manual for additional information.)

R602

*Other batteries for cameras or

computers only.

A.

securely fastened to the

B.

connected only using unmodified

C. charged according to manufacturer recommendations.

A

R611

*The

Compliance with this rule is checked by observing a

>120Ω resistance between either the (+) or (-) post within the APP connector

that is attached to the

All legal motor controllers with metal cases are

electrically isolated. They may be mounted directly to

Note that some cameras, decorative lights, and sensors

(e.g. some encoders, some IR sensors, etc.) have grounded enclosures or are

manufactured with conductive plastics. These devices must be electrically

isolated from the

R609 *Connect main power safely. The following devices shall be connected with 6 AWG (7 SWG or 16 mm2) copper wire or larger as shown in Figure 8‑8:

A.

1

B. a single pair of Anderson Power Products (or APP) 2-pole SB type connectors,

C. the 1 main 120-Amp (120A) surface mount circuit breaker (Cooper Bussman P/N CB185-120, CB185F-120, CB285-120 CB285F-120, CB285120F or Optifuse P/N 153120, 253120), and

D.

the 1 power distribution device (CTR Electronics Power

Distribution Panel,

No additional devices or modifications shall be permitted with the following exceptions:

E. Monitoring circuitry permitted by R625.

F. SB-50 to SB-120 adapters, provided they have been presented for Inspection

G. Termination of wires with appropriate cable lugs

Figure 8‑8 Electrical connection diagram

“SB type” refers to SB type only (e.g. SB-50, SB-120, etc.), not SBS or any other part type beginning with SB. All batteries supplied by FIRST (such as Spare Parts and international batteries) will have a red or pink SB50 connector installed which may not be removed.

The pink connectors included in the

R612

*Must be able to turn

Examples considered not “quickly and safely accessible”

include breakers covered by an access panel or door, or mounted on, underneath

or immediately adjacent to moving

It is strongly recommended that the 120A circuit breaker

location be clearly and obviously labeled so it can be easily found by

While the main breaker must be accessible, consider positioning

or shielding it such that it’s protected from accidental actuation (e.g. it’s

unlikely to be hit by a

R702

*Communicate with the

R620

*Only use specified fuses in

A.

for the

B.

for the

C.

for the

Note that these fuses must be pressed very firmly to seat properly. Improper seating can cause a device to reboot upon impact.

R624

*Use specified wire colors (mostly).

All non-

A. red, yellow, white, brown, or black-with-stripe on the positive (e.g. +24VDC, +12VDC, +5VDC, etc.) connections

B. black or blue for the common or negative side (-) of the connections

Exceptions to this rule include:

C. wires that are originally attached to legal devices and any extensions to these wires using the same color as the manufacturer

D. Ethernet cable used in PoE cables

R812 *Pressure switch requirements. The pressure switch must be connected to the high-pressure side of the pneumatic circuit (i.e. prior to the pressure regulator) to sense the stored pressure of the circuit.

It must be either:

A. Nason P/N SM-2B-115R/443 (wired as described) and/or

The 2 wires from

the pressure switch must be connected directly to the pressure switch input of

the

B. REV Robotics P/N REV-11-1107 (wired as described)

The analog output

of the sensor must be connected directly to analog input 0 of the

The REV Robotics Analog Pressure Sensor may only be used

with

R707

*Limited wireless allowed. The

only forms of wireless communication that may be used to communicate to, from,

or within the

A. those required per R702 and R706

B. tags used for location detection systems if provided by the event

C. RFID

or NFC systems used exclusively within the

Devices that employ signals in the visual spectrum (e.g.

cameras) and non-RF sensors that don’t receive human-originated commands (e.g.

“beam break” sensors or IR sensors on the

R802

*No custom pneumatics and meet

minimum pressure ratings. All pneumatic items must be

A. rated by their manufacturers for pressure of at least 125psi (~862 kPa, 8.6 Bar), or

B. installed downstream of the primary relieving regulator (see R809), and rated for pressure of at least 70psi (~483 kPa, 4.8 Bar)

Any pressure specification such as “working,” “operating,” “maximum,” etc. may be used to satisfy the requirements of this rule.

It is recommended that all pneumatic items be rated by their manufacturers for a working pressure of at least 60 psi (~414 kPa, 4.1 Bar).

R608

*Limit non-battery energy.

Non-electrical sources of energy used by the

A. compressed air stored in the pneumatic system that has been charged in compliance with R806 and R807,

B.

a change in the altitude of the

C.

storage achieved by deformation of

D.

closed-loop

E. air-filled (pneumatic) wheels.

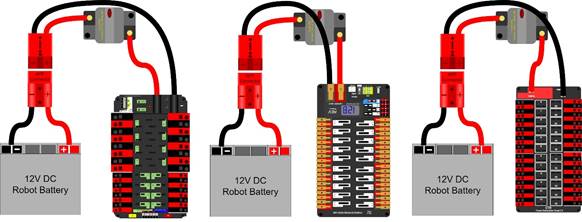

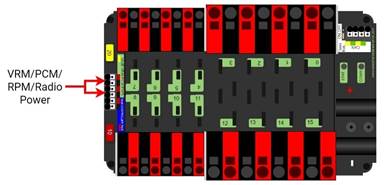

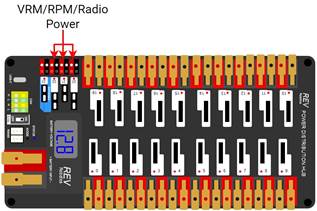

R617 *Power radio as specified – Part 2. The device supplying power to the wireless bridge per R616 must be connected to either:

A.

the designated supply terminals at the end of the

Figure 8‑13

B.

the terminals of the non-switchable fused channels on the

Figure 8‑14

C.

directly to the terminals of any channel on the

Figure 8‑15

Please reference How to Wire an FRC Robot for wireless bridge wiring information.

R625

*Don’t modify critical power paths.

A noise filter may be wired across motor leads or PWM

leads. Such filters will not be considered

Acceptable signal filters must be fully insulated and must be 1 of the following:

-

1 microfarad (1 µF) or less,

non-polarized, capacitor may be applied across the power leads of any motor on

your

- a resistor may be used as a shunt load for the PWM control signal feeding a servo.

Buy me a hot chocolate

Buy me a hot chocolate