G415 Expansion limits. A

If the over-expansion is due to damage and not used for strategic benefit, it is an exception to this rule, and no penalty is imposed.

Violation:

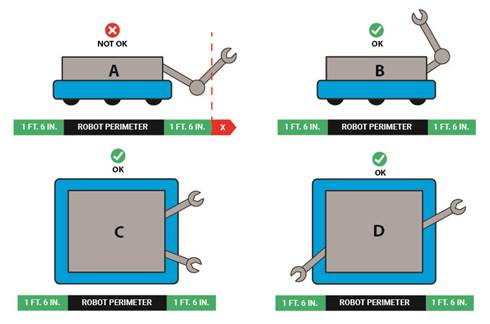

Examples of compliant and non-compliant extensions are

shown in Figure 7‑2.

Figure 7‑2 Examples of compliance and non-compliance of this rule (examples A and B are side views, examples C and D are top views)

The intent of this rule is to prevent piling on a punitive

response to a

A.

a physical device on a team’s

B.

a vertical structural member of a

R105

Figure 8‑2

Teams should expect to have to demonstrate a

See section 7.4.3

R505 *Don’t overload controllers. Each power regulating device may control electrical loads per Table 8‑2. Unless otherwise noted, each power regulating device shall control 1 and only 1 electrical load.

Table 8‑2 Power regulating device allotments

|

Electrical Load |

Motor Controller |

Relay Module |

Pneumatics Controller |

|

AndyMark RedLine Motor Banebots CIM CTR Electronics Minion REV Robotics NEO Brushless REV Robotics NEO 550 REV Robotics NEO Vortex VEX Mini-CIM WCP RS775 Pro |

Yes |

No |

No |

|

AndyMark 9015 VEXpro BAG |

Yes |

No |

No |

|

AndyMark PG NeveRest Snow Blower Motor REV Robotics HD Hex |

Yes |

Yes |

No |

|

Linear Actuator |

Yes (20A breaker max) |

Yes (20A breaker max) |

No |

|

CTR Electronics/VEX Falcon 500 Nidec Dynamo BLDC Motor w/ Controller Playing With Fusion Venom WCP Kraken X44 WCP Kraken X60 |

Yes |

No |

No |

|

Compressor |

No |

Yes |

Yes |

|

Pneumatic Solenoid Valves |

No |

Yes |

Yes |

|

Electric Solenoids |

Yes |

Yes |

Yes |

|

|

Yes |

Yes |

Yes |

E114 *Limit flag and flagpole size. Flags and flagpoles may not be of unreasonable size and weight.

As a guideline, reasonable flags are less than 3 ft. by 5 ft. (~91 cm by 152 cm) in size and weigh less than 2 lbs. (~907g). Reasonable flagpoles may not be more than 8 ft. (~243 cm) long and weigh less than 3 lbs. (~1360g).

R501 *Allowable motors. The only motors and actuators permitted include the following (in any quantity):

Table 8‑1 Motor allowances

|

Motor Name |

Part Numbers Available |

|

|

AndyMark 9015 |

am-0912 |

AndyMark 9015 |

|

AndyMark NeveRest |

am-3104 |

|

|

AndyMark PG |

am-2161 (alt. PN am-2765) |

am-2194 (alt. PN am-2766) |

|

AndyMark RedLine Motor |

am-3775 |

am-3775a |

|

AndyMark Snow Blower Motor |

am-2235 |

am-2235a |

|

Banebots |

am-3830 M7-RS775-18 RS775WC-8514 |

M5 – RS550-12 RS550VC-7527 RS550 |

|

CIM |

FR801-001 M4-R0062-12 AM802-001A 217-2000 PM25R-44F-1005 |

PM25R-45F-1004 PM25R-45F-1003 PMR25R-45F-1003 PMR25R-44F-1005 am-0255 |

|

CTR Electronics Minion |

24-777378 |

WCP-1691 |

|

CTR Electronics/VEX Robotics Falcon 500 |

217-6515 am-6515 |

19-708850 am-6515_Short |

|

Current/former |

Denso AE235100-0160 Denso 5-163800-RC1 Denso 262100-3030 |

Denso 262100-3040 Bosch 6 004 RA3 194-06 Johnson Electric JE-PLG-149 Johnson Electric JE-PLG-410 |

|

Nidec Dynamo BLDC Motor |

am-3740 |

DM3012-1063 |

|

Playing with Fusion Venom |

BDC-10001 |

|

|

REV Robotics HD Hex |

REV-41-1291 |

|

|

REV Robotics NEO Brushless |

REV-21-1650 (v1.0 or v1.1) |

am-4258 am-4258a |

|

REV Robotics NEO 550 |

REV-21-1651 |

am-4259 |

|

REV Robotics NEO Vortex |

REV-21-1652 |

am-5275 |

|

VEX BAG |

217-3351 |

|

|

VEX Mini-CIM |

217-3371 |

|

|

West Coast Products Kraken x44 |

WCP-0941 |

|

|

West Coast Products Kraken x60 |

WCP-0940 |

am-5274 |

|

West Coast Products RS775 Pro |

217-4347 |

|

|

Fans, no greater than 120mm (nominal) size and rated electrical input power no greater than 10 watts (W) continuous duty at 12 volts (VDC) |

||

|

Hard drive motors part of a legal |

||

|

Factory installed vibration and autofocus motors

resident in |

||

|

PWM |

||

|

Motors integral to a |

||

|

1 compressor compliant with R806 and used to compress air

for the |

||

|

|

||

For servos, note that the roboRIO is limited to a max current output of 2.2A on the 6V rail (12.4W of electrical input power). Teams should make sure that their total servo power usage remains below this limit at all times.

Servo mechanical output power is approximated by the following formula (using 6V data reported by manufacturer): Mechanical Output Power (in W) = 0.25 x (Stall Torque in N-m) x (No Load Speed in rad/s). This calculator from the FIRST Tech Challenge documentation can be used to help calculate output power from inputs of various units.

Given the extensive amount of motors allowed on the

AndyMark PG Gearmotors are sold with labeling based on the entire assembly. Assemblies labeled am-3651 through am-3656 contain legal motors specified in Table 8‑1. These motors may be used with or without the provided gearbox.

I105 *Don’t exploit re-inspection. Teams may not use the re-inspection process in I104 to circumvent the weight limit in I103.

This restriction is not intended to prevent a team from

returning to a previous configuration (e.g. due to an unsuccessful upgrade or

failure of a new

Example 1: A

Example 2: A

Example 3: A team arrives at an event with a

R904

*

A. be longer than 5 ft. (~152 cm),

B.

be deeper than 1 ft. 2 in. (~35 cm) (excluding any items that are held

or worn by the

C. extend more than 6 ft. 6 in. (~198 cm) above the floor, or

D.

attach to the

There is a 4 ft. 6 in. (~137 cm) long by 2 in. (nominal)

wide strip of hook-and-loop tape (“loop” side) along the center of the

Please note that while there is no hard weight limit,

R101

*

To determine the

Example: A

Figure 8‑1

R710 *Only specified modifications to control system

devices permitted. The Driver Station Software, roboRIO,

Please note that the Driver Station Software is a separate application from the Dashboard. The Driver Station Software may not be modified, while teams are expected to customize their Dashboard code.

A. User programmable code in the roboRIO may be customized.

B. Motor controllers may be calibrated as described in owner's manuals.

C. Fans may be attached to motor controllers and may be powered from the power input terminals.

D. If powering the compressor, the fuse on a Spike H-Bridge Relay may be replaced with a VB3A-20A Snap-Action circuit breaker.

E. Wires, cables, and signal lines may be connected via the standard connection points provided on the devices.

F. Fasteners

(including adhesives) may be used to attach the device to the

G. Thermal interface material may be used to improve heat conduction.

H. Labeling may be applied to indicate device purpose, connectivity, functional performance, etc.

I. Jumpers may be changed from their default location.

J. Limit switch jumpers may be removed from a Jaguar motor controller and a custom limit switch circuit may be substituted.

K. Device firmware may be updated with manufacturer supplied firmware.

L. Integral wires on motor controllers may be cut, stripped, and/or connectorized.

M. Devices may be repaired, provided the performance and specifications of the device after the repair are identical to those before the repair.

N. The cover may be removed from the Talon SRX or Talon FX data port.

O. Electrical tape may be applied to the aluminum plate inside the wireless bridge.

P. The

input terminal cover from the

Q. The roboRIO 2.0 SD card may be replaced with an SD card of any capacity.

R. adding insulating material to exposed conductors.

S. replacing

control system power terminal blocks (e.g.

T. tape may be applied for debris protection.

Please note that while repairs are permitted, the allowance

is independent of any manufacturer’s warranty. Teams make repairs at their own

risk and should assume that any warranty or return options are forfeited. Be

aware that diagnosing and repairing

For more information about modification O, please see this OM5P-AC Radio Modification article.

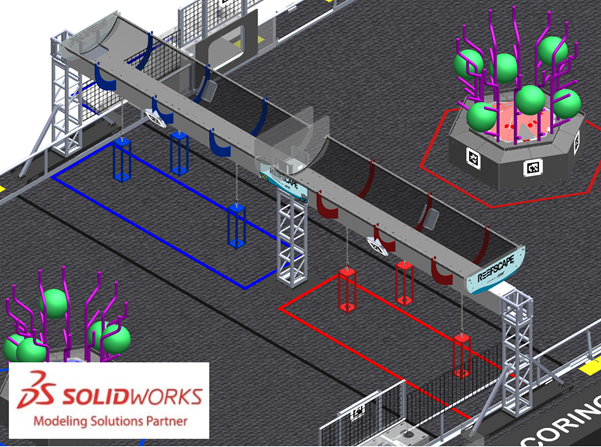

5.4

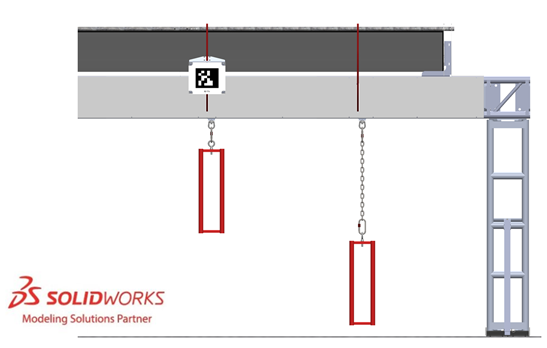

BARGE

Figure 5‑9

The

The

5.4.1

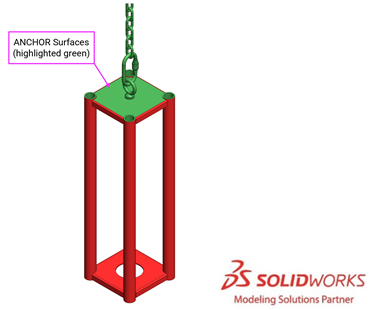

CAGE

Figure 5‑10 Shallow (left) and Deep (right) staged

A.

the top surface of the

B. the chain,

C. both carabiners,

D.

the portion of the eye bolt extending above the

E.

the eye nut attached to the

F.

the upper end surfaces of the

G.

the inside surfaces of the

Figure 5‑11:

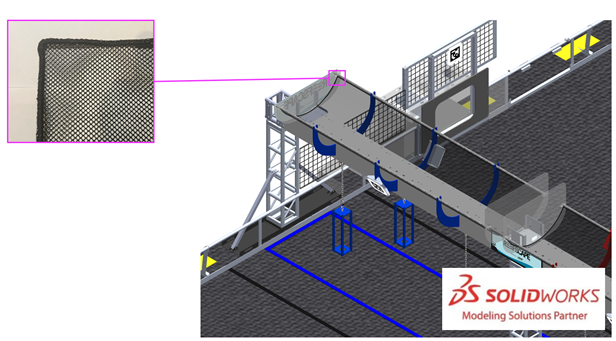

5.4.2

NET

Figure 5‑12

A

G435

The

A. 3 in

the holders on top of the

B. 1 at

the end of the

Violation:

R104

Be sure to consider the size of the

Note that rules contained in section 8.4

R301

*Individual item cost limit.

No individual, non-

Teams should be ready to show

The Analog Devices IMU

The FMV of a

The FMV of

The FMV of FABRICATED parts is the value of the material and/or labor, except for labor provided by team members (including sponsor employees who are members of the team), members of other teams, and/or event provided machine shops. Material costs are accounted for as the cost of any purchasable quantity that can be used to make the individual part (i.e. the purchasable raw material is larger than the FABRICATED part).

Example 1: A team orders a custom bracket made by a company to the team's specification. The company’s material cost and normally charged labor rate apply.

Example 2: A team receives a donated sensor. The company would normally sell this item for $450 USD, which is therefore its FMV.

Example 3: A team purchases titanium tube stock for $400 USD and has it machined by a local machine shop. The machine shop is not considered a team sponsor but donates 2 hours of expended labor anyway. The team must include the estimated normal cost of the labor as if it were paid to the machine shop and add it to the $400 USD.

Example 4: A team purchases titanium tube stock for $400 USD and has it machined by a local machine shop that is a recognized sponsor of the team. If the machinists are considered members of the team, their labor costs do not apply. The total applicable cost for the part would be $400 USD.

It is in the best interests of the teams and FIRST to form relationships with as many organizations as possible. Recognizing supporting companies as sponsors of, and members in, the team is encouraged, even if the involvement of the sponsor is solely through the donation of fabrication labor.

Example 5: A team purchases titanium tube stock for $400 USD and has it machined by another team. The total applicable cost for the part would be $400 USD.

Example 6: A team purchases a widget at a garage sale or

online auction for $300, but it’s available for sale from a

If a

If the modules are designed to assemble into a single configuration, and the assembly is functional in only that configuration, then the total cost of the complete assembly including all modules must fit within the price constraints defined in this rule.

In summary, if a

Example 7:

Example 8:

Example 9:

E603

Practice Field attendance is

limited. Only team members actively working on the

The intent of this rule is to limit the number of people

directly next to

Teams may have additional team members watching from a

distance, provided the venue has space, but those members should be a safe

distance from all

R102

*

If a

The allowance for minor protrusions in this rule is

intended to allow protrusions that are both minor in extension from the

If a

R502

*Only 4 propulsion motors. A

Examples that are not considered propulsion motors include:

A. motors that primarily alter the alignment of a wheel in

contact with the

B. motors that run

C. motors that change the speed of the drive wheels using a

shifting